Published On Dec 14, 2021

Part 1: This screw extruder can melt a jaw dropping 1 kg of plastic pellets per hour. Learn how this will be used to print furniture!

Files, Parts, and Info: https://www.drdflo.com/LF3DP.html

Large Format Printer Playlist: • Large Format 3D Printer Build Series

D-Flo's Amazon Store: https://www.amazon.com/shop/dr.d-flo

📷 Follow Dr. D-Flo on the Gram: / dr.dflo

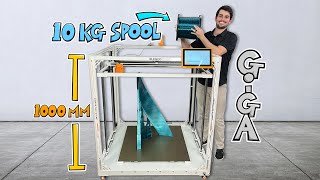

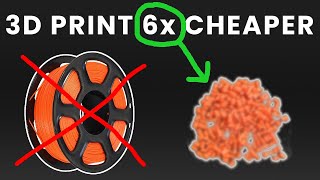

Dr. D-Flo is taking his shop’s additive manufacturing capabilities to the next level by building an industrial scale 3D printer with a build envelope of 4’x4’x4’ (1220mm x 1220mm x 1220mm). When DIYing a printer this large, a normal filament extruder will not be able to pump out enough plastic to fill this build volume. Therefore, Massive Dimension’s MDPH2 pellet extruder capable of depositing 1 kg of molten plastic an hour will be used to generate the layers for some massive objects. Dr. D-Flo talks about the benefits and limitations of using pellets as a feedstock and even explores how to add colorants to the plastic pellets to achieve color extrusions.

The MDPH2 weighs almost 20lbs (9kg) and to be able to move this beast precisely within a 4x4’ work area will require a rigid and powerful linear motion setup. For this reason, Dr. D-Flo opted for OpenBuild’s C-Beam Tension XL Linear Actuators, which he has configured into a motion platform where the extruder is moved in all 3 dimensions (stationary bed design).

Watch Dr. D-Flo plasma cut and mill custom pieces to bring this large format 3D printer to Life.

Table of Contents:

00:00 – Introduction

00:33 – Pellet Extruder

03:30 – Duet 3 Microcontroller

04:43 – Extruding Pellets

09:17 – Switching Temperature Probes

11:57 – Linear Motion

16:36 – Frame

17:47 – Build Plate

22:07 – Bed Leveling System

#Massive #DIY #3DPrinter