Published On Jan 12, 2021

Originally, these multipurpose tools were called Schweizer Offiziers-und Sportsmesser, but that name was too clunky and was eventually shortened to ‘Swiss Army knife’ by American soldiers.

Subscribe to PopMech: http://bit.ly/SUBSCRIBEtoPOPMECH

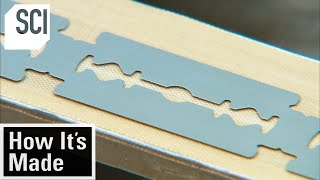

The first step in the the production process is to stamp the raw material to create the different parts of the knife. This is followed by a polishing process in which the metal blades are tossed into a container full of ceramic stones and then pulled out by a magnet. In order to harden it, the metal sits on a conveyor belt and goes through an oven.

“Inside we have a temperature of 1,050 degrees,” says senior product marketing manager at Victorinox, Urs Wyss. “This heat changes the structure of the steel.” The metal then gets ground to ensure sharpness and assembly continues.

Victorinox was started by Elsener’s great grandfather, Karl, in 1884 and continues to be run as a family business out of Schwyz, Switzerland today.

--------------------------------------

Facebook: / popularmechanics

Twitter: / popmech

Instagram: / popularmechanics

Pinterest: https://www.pinterest.com/popmech/?au...

#madehere #swissarmyknife #popmech