Published On Dec 3, 2022

▶ Visit https://brilliant.org/NewMind to get started learning STEM for free, and the first 200 people will get 20% off their annual premium subscription

Sandpaper belongs to a class of abrasive products known as coated abrasives. These products are composed of an abrasive element bonded to a backing material such as paper, fabrics, rubber, metals or resins and they generally possess some degree of flexibility. King Solomon is mentioned to have used a mysterious worm or an abrasive substance called the Shamir that had the power to cut through or disintegrate stone, iron and diamond. In the 13th century, Chinese craftsmen were known to bond sand, crushed shells and sharp seeds onto parchment with natural gum. Other notable natural substances that have been used as abrasive tools include Shark skin, Coelacanth scales, and boiled and dried rough horsetail plan.

INDUSTRIAL ERA

After mastering the process, Oakley would go on to found John Oakey & Sons Limited in 1833 with the goal of mechanizing the process and within a decade Oakley had not only developed new adhesive techniques and manufacturing techniques that enabled the mass production of sandpaper but also created the first glass based coated abrasives. These products used small grains of ground-up glass or garnet called frit that are far more durable than sand, and also retain a sharp-edged structure as it wears down, producing a longer lasting abrasive cutting action. An initial attempt of producing their own grinding wheels was met with little success so the company, now branded as 3M soon transitioned into the coated abrasives industry. 3M’s initial venture into the market using natural abrasives was still plagued with quality issues and its reputation began to suffer.

Three-M-ite was a cloth backed coated abrasive that relied on a new class of synthetic abrasives. These abrasives were a direct result of the advent of electric furnace technology that allowed a combination of base materials to be fused by heating them to temperatures above 2000°C or 3600°F, forming new crystal structures with favorable abrasive properties .

NEW TYPES OF SANDPAPER

In 1921, the company introduced the world’s first water-resistant coated abrasive called Wetordry. When bonded to a waterproof paper backing and used with water, silicon carbide sandpaper dramatically enhanced many of the key properties that define the effectiveness of a coated abrasive.

HOW SANDPAPER WORKS

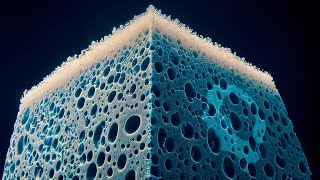

The effectiveness of this action is highly dependent on the shape of the abrasive grain, with sharper edges producing more localized pressure at the interface points of both materials. The durability of a sandpaper is primarily determined by the relative hardness between the abrasive and the work material, the adhesion properties and size of the abrasive grain or grit size, and its ability to resist loading, where ejected material is trapped between the grains.

A NEW AGE OF SYNTHETIC ABRASIVES

Alumina-Zirconia is an incredibly tough and hard abrasive that offers nearly twice the performance of aluminum oxide in both efficiency and durability. It was also relatively easy to mass manufacture and quickly became a popular choice for metal working abrasive products.

SOL-GEL CERAMICS

In the early 1980’s, a revolutionary process that would dramatically improve abrasive performance would be introduced by 3M with the industry's first steps into nanotechnology. This new class of ceramic nanoparticle abrasives are produced using a method called the sol-gel process. This new abrasive became the foundation of their new Cubitron product line, and it would soon gain wide acceptance in the metalworking industry both in coated product form and as bonded grinding tooling.

MICROREPLICATION

In both synthetic and natural grain abrasives, the inconsistent particle shape of crushed grain creates inconsistent grinding and plowing action on the workpiece. These first trials in shape manipulation initially produced a coarsely shaped repeating pyramid mineral that was initially introduced in 1992 as a low grit metalworking aluminum oxide based product called 3M Trizact. By the turn of the century, 3M would introduce a new class of product line based on precision grain shape or PSG technology.

In this process a casting film is used to roll a microstructure onto a wet uncured abrasive gel coating. As this occurs a combination of UV light and heat is applied under the roller’s pressure, curing the abrasive in its designed structure. Microreplication would first be used to further refine the Trizact product line. Cubitron II utilized a unique standing ceramic aluminum oxide triangle microstructure that not only had an extremely sharp tip that would cut through the work material instead of plowing through it , but by design, would fracture to produce a new sharp edge as it wore, effectively becoming a self sharpening grain.

--

SUPPORT NEW MIND ON PATREON

/ newmind