Published On Jul 2, 2020

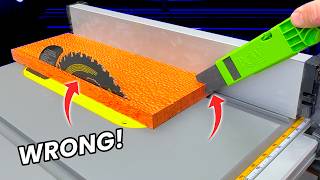

I required the capability to cut metal tubing at a very high precision. I did not feel like spending the large amount of money required to get a cold cut saw. Instead, I purchased a 10" ferrous metal blade and adapted my old compound mitre saw to utilize this blade.

I had to use a washer to adapt the saw arbor to fit the new blade. The largest challenge was getting the motor to spin at less than half its original speed, this can theoretically be done in several manners, but I found the microwave transformer to work best in my application.

The total cost for this project was around 100$. I simply had to purchase the blade itself, and the electric components for the transformer. Old microwaves can be an excellent source for electronic components, such as small motors, magnets, switches, transformer cores, and chokes.

0:00 - Mounting Ferrous Metal Blade

2:54 - Testing A Dimmer Switch

4:10 - The Difference Between Dimmers And Transformers

6:14 - How To Remove The Secondary Coil Of The Transformer

6:46 - Approximating Number Of Turns For New Coil

8:06 - Winding Transformer

9:07 - Transformer Assembly

14:16 - Whoops, Need Less Turns

16:32 - Testing Cold Cut Saw

16:57 Angle Grinder Comparison

17:28 Post Performance Examination

19:19 Outro