Published On Nov 18, 2021

Bryan teaches the Kalos techs a Gas Furnace Class. He covers many types of furnaces, especially 80% gas furnaces in Florida. They also talk about furnace troubleshooting, maintenance and do some hands-on training at the end.

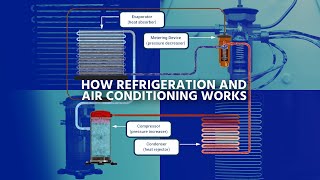

Furnaces use a flame, or the rapid oxidation of fuel, to heat the air. The furnace achieves combustion with a heat source, fuel, and oxygen. Furnaces may use one of two main fuel types: natural gas and LP (liquefied petroleum). Propane and butane are heavier than natural gas, so they are more dangerous because they displace oxygen and fill the room from the bottom up.

The furnace sequence of operation starts with a W call, which is a 24v call for heat on the W terminal (white wire). You don't want a G call because the fan would circulate cold air before the furnace lights, and we want to observe the flame before and after the blower starts. The flame should stay straight; if the flame wiggles a lot, you could have air leakage. Another potential cause of a wiggly flame is a cracked heat exchanger (which is quite uncommon in Florida).

After the furnace receives a W call, the circuit board will check the inducer fan; under typical conditions, the inducer fan will start. (The inducer fan typically uses a shaded-pole motor.) Then, the pressure switch ensures that you have a proper draft. The pressure switch must have sufficient negative pressure in an 80% furnace.

When you have a proper draft, you start the ignition sequence. After ignition, the gas valve opens. A flame rod or flame rectifier would prove that the flame is burning; if the flame is not burning, unspent gas could build up and cause an explosion. After everything has been proven, the blower will start up and move heat through. If any safeties can't prove air or flame, the furnace will shut off.

We use four main types of ignition: standing pilot, direct spark (DS), intermittent spark (ISI), and hot surface (HSI). Standing pilot ignition requires us to light the pilot, and a thermocouple proves flame on the pilot light. Direct spark uses a spark to light the main burner. Intermittent spark ignition relies on a pilot that is NOT lit all the time; the spark igniter can also sense flame. The most common ignition type is hot surface ignition, which relies on a rod that heats up. Hot surface igniters are common fail items. The gas valve opens and puts gas in the main burner.

When a furnace goes out on rollout, the rollout switches will open. High limit switches trip when the furnace gets too hot, which usually indicates low airflow.

Natural-draft furnaces aren't very common in our Central Florida market, but we often see 80% non-condensing open combustion induced draft furnaces. The latter pulls air in from around the unit in the combustion air zone, so these units can't be stuffed in closets.

The biggest dangers of gas furnaces are gas leaks, carbon monoxide, and flame rollout. Low-level carbon monoxide detectors can pick up carbon dioxide, and we recommend offering them to all of our customers who have gas furnaces.

We prioritize safety over efficiency in our market, so we try to look for improper venting, poor gas line insulation (or other gas line leak risks), backdrafting or orphaned water heaters, improper gas pressure settings, high ambient CO during operation, CO in the home, and improper combustion air.

Useful tools for working on gas furnaces include combustion analyzers, low-level CO detectors, combustible gas leak detectors, and manometers. You'll want to use your manometers to be aware of gas pressure and static pressure. You will use your manometer to set gas pressure (inlet AND outlet pressure), your personal CO monitor to measure ambient CO, and your combustible gas leak detector to check for leaks.

You'll put your visual inspection skills to use on gas furnaces, checking for corrosion and other abnormalities. Check the surrounding areas too.

When servicing gas furnaces in Central Florida, we start by checking and cleaning the burners. Then, we check existing CO monitors and advise customers about low-level CO monitors. We then inspect and clean the flame rod/sensor. After that, we inspect the venting and combustion air and check for gas leaks or improper piping. Then, we actually run the system and check the flame during operation. We then measure CO and gas pressure. We finally check the temperature rise.

Bryan also covers:

Fuel concentration

Proving inducer air

Pressure in the flue

Gas pool heater ignition

Gemini gas valves

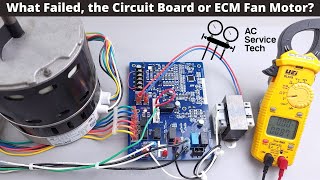

Inducer fan motor issues

Venting for high-efficiency furnaces

Testing a flame rod/sensor

Adjusting Gas Pressure on a Standard and Gemini Furnace Valve video: • Adjusting Gas Pressure on a Standard ...

#Bertlife Gas Leak video: • Adjusting Gas Pressure on a Standard ...

Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/.

Learn more about the 2022 HVACR Training Symposium at https://hvacrschool.com/symposium/.