Published On Feb 26, 2021

►Full project details and links https://www.easycomposites.co.uk/lear...

►Video about the starter kit • 3D Print to Carbon Fibre Development ...

Further information and links ▼

►Thanks to Dynamism for help and advice with the 3D printer https://dynamism.com/3dp-cf

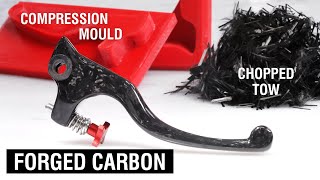

In this video tutorial we demonstrate how a genuine carbon fibre part can be created by hand laminating directly into a 3D printed mould.

In the tutorial we begin by 3D printing the female mould on a conventional FDM printer (an Ultimaker S3) which we then coat with PVA release agent. The carbon fibre part is then hand laminated directly into the mould using no specialist tools or equipment. Once the parts have cured they are demoulded, some minor repairs are made and then they are coated and finished using XCR coating resin.

Except for the 3D printer and filament, all materials used in the tutorial are available from Easy Composites, including the EL2 Laminating Epoxy and 2x2 Twill carbon fibre cloth which are both included in Easy Composites' Carbon Fibre Laminating Starter Kit.