Published On Apr 3, 2020

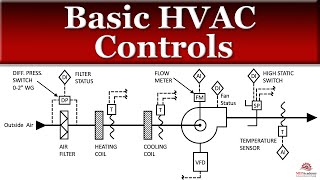

Lesson 7 in the video series on building automation systems. BAS 101 training class or building automation system basics. This lesson dives into the controller, programming, and niagara workbench.

This lesson gets further into the BAS training simulator purchased from DDC Support services. I've utilized some of the training material supplied with their system - www.DDCsupportservices.com

From the website:

The PT-181 is a portable training unit specifically designed for the DDC (Direct Digital Controls) industry. It is packaged with curriculum that is both embedded in the Trainer and contained in a written workbook resulting in a highly interactive student – trainer experience. The PT-181 incorporates some of the most popular DDC devices currently in use. The web-enabled DDC controller allows the student to access the Trainer using a standard web browser and HTML5 or JAVA WebStart®. All of the DDC devices are interfaced with the main controller via hardwired or network connections. BACnet IP (Ethernet) and MS/TP (RS485 serial) networks are utilized allowing the student to gain exposure to the most popular BAS networks in use. The PT-181s can be operated stand alone or easily networked together for use in a learning center environment. Onboard temperature, CO2, humidity, and motion sensors are included. Graphical object oriented programming is presented using the Niagara N4 Framework®

COPYWRITE:

Important User Information

The documentation presented in this manual is intended to be used as a learning tool to be administered by qualified professionals. Whether printed or electronic, this documentation is intended for use as a learning aid when combined with the Portable or Fixed Training Devices provided and approved by DDC Support Services.

Those responsible for the application and use of those products must satisfy themselves that all necessary steps have been taken to ensure that each application and actual use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards in addition to any applicable technical documents.

In no event will DDC Support Services be responsible or liable for any indirect or consequential damages resulting from the use and application of the products described in this documentation. DDC Support Services does not assume responsibility or liability for damages of any kind based on the alleged use of or reliance on, this Documentation.

This document and the devices provided by DDC Support Services training equipment does not constitute an endorsement of any of the Manufacturers or Marketing Vendors of said devices.

This documentation is not intended to serve as a substitute for mandatory Manufacturers certification and device specific training.

No patent liability is assumed by DDC Support Services with respect to use of information, circuits equipment, or software described in the documentation.

Except as specifically agreed in writing as part of a maintenance support contract, equipment users are responsible for:

• Properly using, calibrating, operating, monitoring and maintaining all DDC Support Services training products consistent with all DDC Support Services or third-party provided instructions, warning, recommendations and documentation.

• Ensuring that only properly trained personnel use, operate and maintain the products at all

times.

• Staying informed of all product updates and alerts and implementing all updates and fixes.

• All other factors affecting the products that are outside of the direct control of DDC Support Services.

Reproduction of the contents of the Documentation, in whole or in part, without written permission of DDC Support Services is prohibited.

USED BY PERMISSION