Published On Jul 26, 2021

▶ C'mon over to https://realpars.com where you can learn PLC programming faster and easier than you ever thought possible!

=============================

▶ You can read the full post here

https://realpars.com/contactor

=============================

⌚Timestamps:

00:00 - Intro

00:39 - What is a contactor?

00:55 - Why contactor is used?

02:44 - Contactor vs. relay

03:39 - How to wire a contactor

03:43 - 1) Coil terminals

04:53 - 2) Contacts terminals

05:55 - 3) Auxiliary contact terminals

06:10 - How does a feedback contact work?

07:08 - How to wire a contactor to the PLC and motor

=============================

In this video, we will explain what a contactor is, how they work, how to wire a contactor, and the difference between a contactor and a relay.

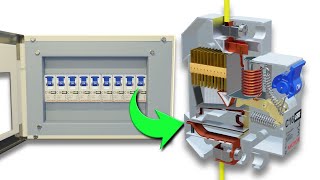

A contactor is a device that is for making and breaking an electrical power circuit. For example, we usually use a contactor for turning on and off an electrical motor.

Why do we need to use a contactor? Can't we connect the motor directly to the PLC? Well, the short answer is no. Because you don't want to connect a high voltage electric motor to your shiny expensive PLC directly. This will damage the PLC cards if there are any electric surges on the motor's side.

We use a contactor to connect the PLC to the motor indirectly and safely. All contactors have a low voltage coil. We connect the PLC output to this coil. This coil usually works with a 24-volt DC signal.

Once the coil is energized, an electromagnetic field will be created. This electromagnetic field then causes the contacts to be closed and that's how the 3-phase power will reach the motor and can turn it on. So, there is no electrical connection between the coil and the contacts.

In the normal state and when the coil is not energized, the contacts are open and when a 24-volt DC signal is sent from the PLC, the coil will be energized, the contacts will close and the motor turns on.

A relay works the same way as a contactor. That means a relay also has a coil and some contact. When the coil is energized, the contacts will close.

But here is the difference... a relay is usually used for smaller devices with lower current and voltage rates. A contactor, however, is used for bigger devices with higher current and voltage rates.

Let’s talk about the wire terminals on the contactors.

1) On the front of the contactor, we see two wire terminals of A1 and A2. This is where we can connect a 24-volt DC power to the coil to energize it.

The coil may work with different voltages such as 12-volt DC, 24-volt DC, or maybe 220-volt DC.

Depending on the type of the contactor, the coil can also work with a 24, 120, or 220-volt AC power.

2) On the other side of the contactor, we have six other wire terminals. The wire terminals on the top are labeled from left to right with L1, L2, and L3. The wire terminals on the bottom are labeled from left to right with T1, T2, and T3.

The L1, L2, and L3 terminals are where the power wires connect to the contactor. The T1, T2, and T3 terminals are where the device wires connect to the contactor.

3) We have another set of wire terminals on the front end labeled as NO or normally open. This is a simple normally open contact referred to as an auxiliary contact or a feedback contact.

This contact is used to send a signal to the PLC input about the contactor's health. When the coil is energized and the three main contacts are closed, the feedback contact will be closed as well and send a signal to the PLC input.

We have discussed this more in our level 2 PLC programming course and there is a sample PLC program that shows why we always need to use a feedback contact and how to use that contact in the PLC program to get notified when the contactor is broken: https://bit.ly/36P7cbd

You also need a start and stop switch to be connected to the PLC input.

- When you press the start switch, the coil will be energized, the contacts will be closed and the motor will be turned on.

- When you press the stop switch, the coil will be de-energized, the contact will open and the motor will turn off.

=============================

Missed our most recent videos? Watch them here:

https://realpars.com/capacitive-sensor

https://realpars.com/photoelectric-se...

https://realpars.com/inductive-sensor

=============================

To stay up to date with our last videos, make sure to subscribe to this YouTube channel:

http://bit.ly/realpars

=============================

TWEET THIS VIDEO https://ctt.ac/3Q3o3

=============================

Follow us on Facebook: / therealpars

Follow us on Twitter: / realpars

Follow us on LinkedIn / realpars

Follow us on Instagram / realparsdotcom

#RealPars #Contactor #PLC